Process Observer |

Because peer to peer architecture leads to communication chaos and functions centralization in a super-system means authoritarian subordinate we need a new approach.

This topic contains the following sections:

This approach – called Process Observer - to overcoming communication chaos and drawbacks of the centralized architecture is based on the:

Novel architecture

Smart process data transfer algorithms

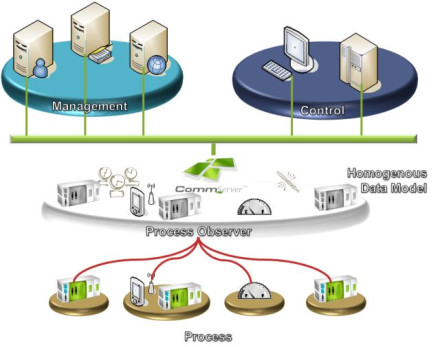

The first idea is an innovative approach to the systems integration problem, where instead of establishing links (ad-hoc associations between systems which lead to the communication chaos) or applying an universal supersystem, we use a so called Process Observer – a standardized, homogenous real-time model of the process layer. It allows to share data from plant floor devices by the process control and management systems, using international standards of data exchange.

The process observer is a kind of the virtual layer, which is a “big picture” of the underlying process layer composed of unit data randomly accessible by means of a unified and standardized interface. Additionally, basing on current manufacturing data, the picture may be enriched by adding modeled data, non-available directly. Thereby, the structure of the links becomes systematic and, on the another hand, the existing functionality of the upper layers are preserved. Now, they can gather the process data in an unified, standardized way.

The key to successful implementation of the Process Observer archetype is to provide upper layer systems a standardized, homogenous real-time model of the process layer. The OPC Unified Architecture seems to be the only candidate to withstand these requirements. |

To use the Process Observer concept, appropriate communication technologies supporting the process data acquisition are necessary. Those technologies are a set of algorithms and functions which provide a smart process data transfer. The idea of the smart data transfer is based on the following rule:

Transfer only once and only the most important data at any instant. |

This functionality is of vital importance to communication in systems with numbers of remote terminal units spread over a large geographical area, e.g. heat counters, energy consumption counters. In other words, wherever the application of dedicated to communication infrastructure is impossible or impractical and communication services offered by local providers must be employed. Innovative optimization algorithms of communication resources utilization are based on minimizing the process data transfer bandwidth as a function of the current state of the production process. They allow to:

Adapt the data sampling period according to the process current needs.

Reduce requirements concerning the channel bandwidth significantly.

Eliminate the need to transfer the same data many times by selectively activating only one communication path with remote terminal units.

Take advantage of redundancy and continuous availability control of all communication paths.

A communication server fully implementing the PO archetype is CommServer. Using the CommServer as the Process Observer to integrate applications in an enterprise enables to make the communication links structure systematic and randomly access process data in an unified and standard manner by upper layer systems. Thereby, once read, data is available for all components (systems). It greatly improves the efficiency of the data acquisition and simplifies the data transfer in any enterprise. |